Jyoti CNC Automation Ltd

CNC Machines: Proxy to manufacturing growth in Defense, Aerospace and EMS

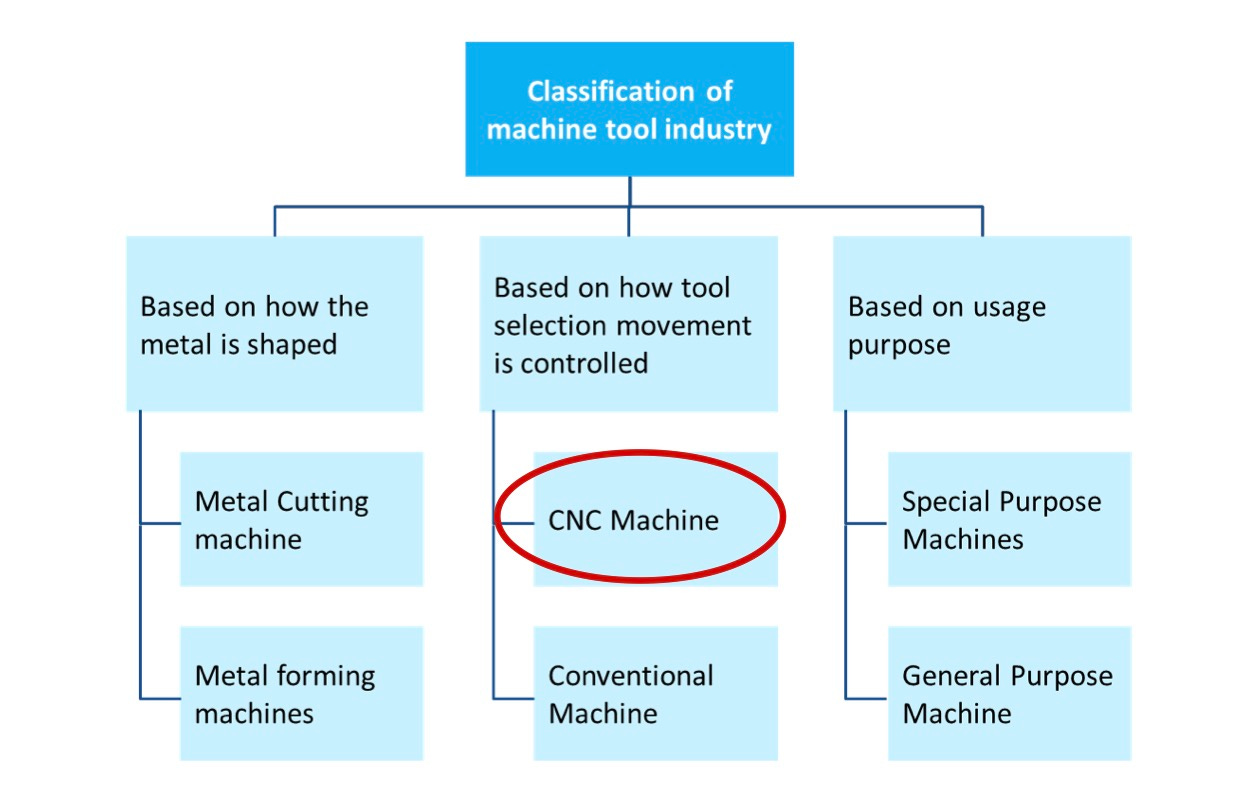

A Primer on CNC Machines

CNC Machining has revolutionized modern manufacturing whereby the control of machine tools (milling, lathes. etc.) is automated through the use of computer technology.

The importance of CNC machines is accentuated in manufacturing processes where precision and consistency are paramount requisites eg in aerospace, medical devices, defense equipment, and electronics manufacturing. The reprogramming of CNC allows for seamless transitions between products leading to time-saving in the manufacturing process hence offering precision, efficiency, and versatility. Manual operations cannot handle complex machinery with the level of accuracy that computerized controls do.

CNC Machines can be segmented based on their operations into - Mills, Lathes, Turning centers, Grinders, Drilling machines and Boring Machines

CNC Machining Centers

A CNC machine center is an advanced machine tool which allows milling, lathing, and drilling operations etc. on a single machine tool i.e. a versatile machine operated by a computer through a sequential program of machine control instructions which may be written by a coder or generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software.

The CNC machining centers can be broadly categorized into the following based on the orientation of the spindle.

a Vertical machining center (VMC):

b Horizontal machining center (HMC)

c Universal machining center (UMC)

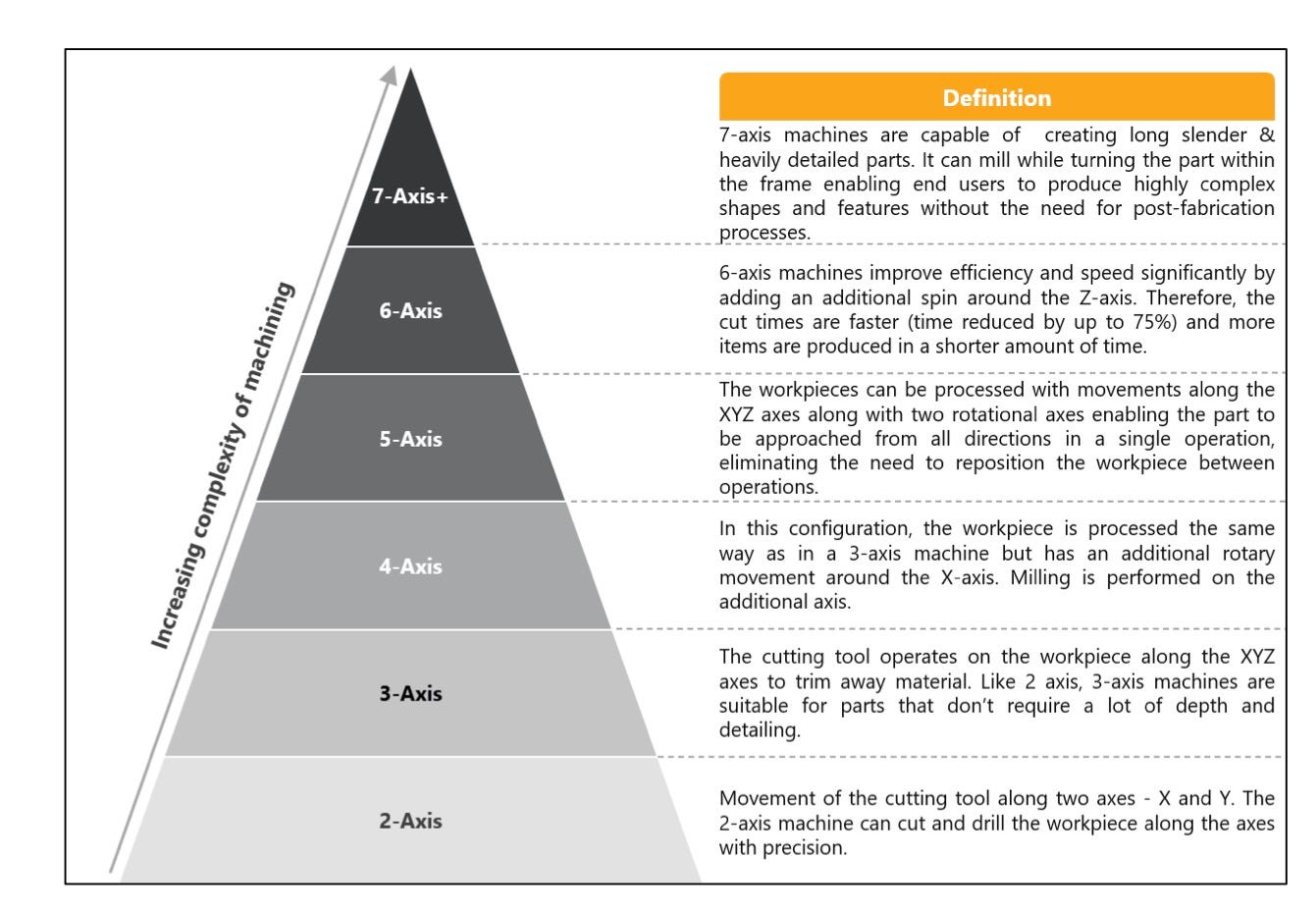

Classification on the basis of Axis in CNC Machines:

CNC machines operate on a system of axes that are used to control the movement of the machine's tools and workpieces. These axes are typically linear (X, Y, and Z) and rotary (A, B, and C). Axes refer to the directions in which the machine can move a tool or workpiece. Linear Axis allows machines to operate in a plane while the Rotary Axis allows the machine to manipulate the workpiece or tool at various angles, enabling more complex and precise machining operations.

As a layman, the more the number of moving parts or the degrees of freedom with which the machine can work, the more complex and versatile it is. Add to it the precision, level of automation, speed, and other suites of self-diagnose/maintenance software or AI integration, etc.

JYOTI CNC Automation Ltd.

Jyoti CNC Automation Limited is one of India's largest CNC machine tool manufacturers.

The Company’s range of products that includes CNC Turning Centres, Turn-Mill Centers, Vertical Machining Centers (VMC), Horizontal Machining Centers (HMC), and advanced 5-axis Machining Centers, along with solutions for Industry 4.0 and Artificial Intelligence (AI).

Vertically integrated company with in-house manufacturing of machine components such as spindles, tool-changers, pallet changers, rotary tables and universal heads in-house. The company has its own R&D Centers, Foundry, Machine Shop, and Sheet Metal Unit. Also has in-house design capabilities.

Focus on R&D

Dedicated R&D facilities at Rajkot and Strasbourg.

Over the last 20 years the company has developed more than 200 plus product areas for the different manufacturing processes

Capabilities in higher complexity products eg. collaborated with IIT Chennai manufacture, 5–axis multitasking machines; developed its own platform on Industry 4.0 called 7th Sense

Has a diverse customer base. Some of the marquee customers include ISRO, Brahmos, Harsha Engineers, Bosch, Tata Advanced Systems etc.

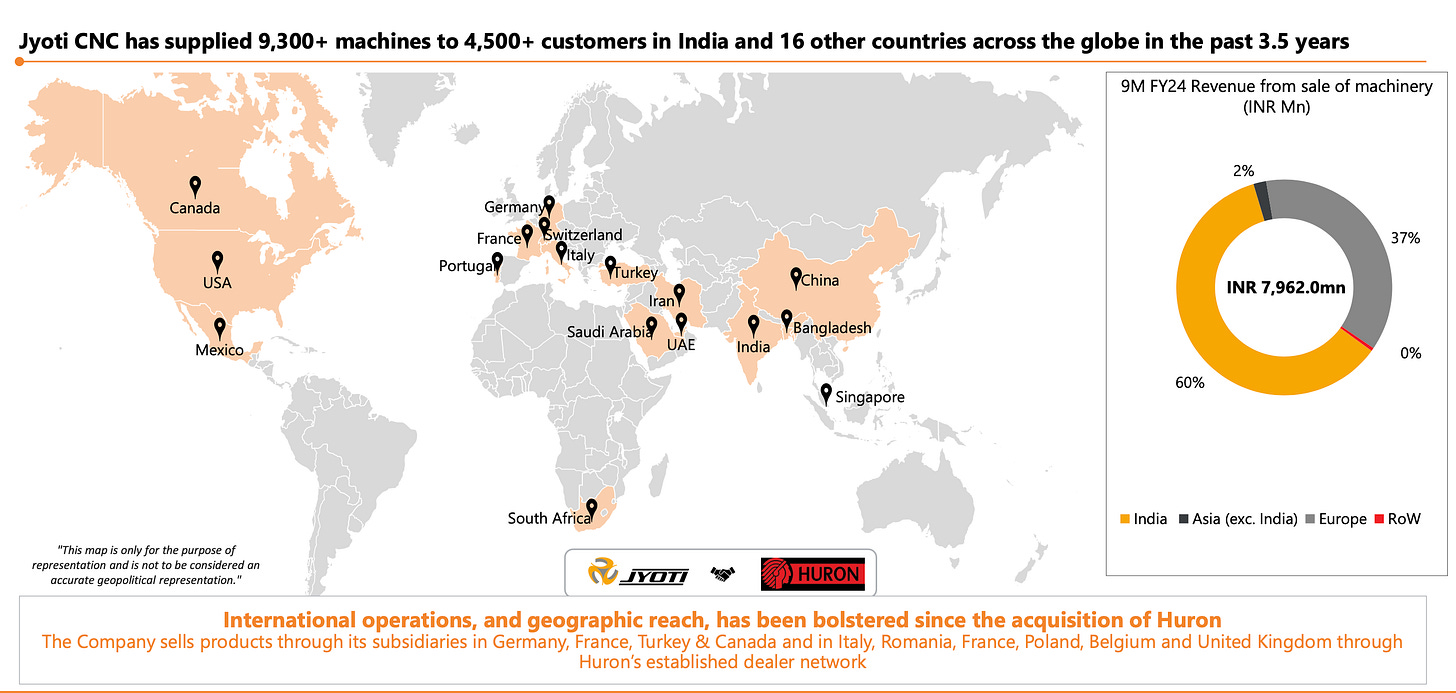

Exports constitute ~ 40% of revenue.

Acquisition of Huron in 2007: Strategy for Tech Infusion

In 2007, it acquired French machine tool giant Huron Graffestaden S.A.S which bolstered its technological capabilities

Huron is reputed for 5-axis machining technology.

Acquisition provided access to a diverse global customer base, across aerospace, defence and other high-end engineering application industries

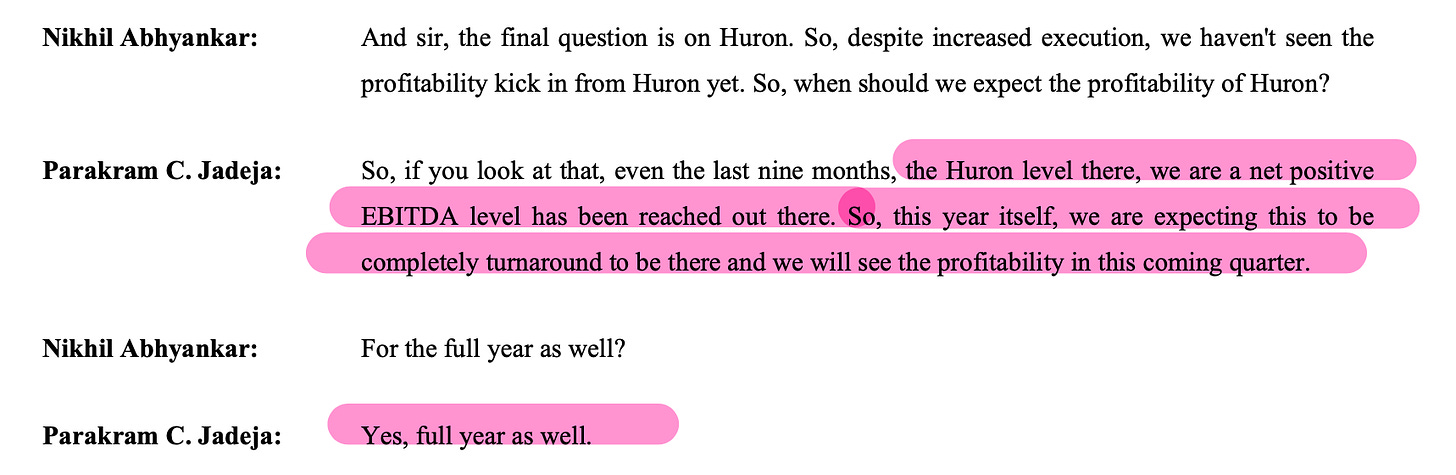

Huron is a turnaround story. As per management, Huron will be EBITDA positive for the full year.

End user Industries:

Aerospace and Defence: (55% of order book)

➔ 1500 crores of orders in the pipeline

Auto and Auto Components (14% of order book)

General Engineering (5% of order book)

Dies and Moulds (8% of order book)

EMS (12% of order book)

➔In the EMS space they have developed the product for manufacturing of mobiles, tablets and watches. It competes mainly with players from Germany and Japan as the company is more into high end machines (as per management)

➔Received sample orders from 2 new customers in EMS segment.

➔ 500 crores of orders in pipeline

➔ Working on New Product Development to cater to new lines of business within the EMS space – products at various stages of approval.

➔ On an annual basis, the company expects EMS to contribute a significantly larger share in revenue.

➔ Set up 2 dedicated assembly lines for the manufacturing of machines for the EMS industry in Rajkot

Others (6% of order book)

Overall has an order book of ~3200 crore to be executed in next 1.5 years

Growth plans: the company has outlined three phases for growth.

Ist Phase: the de-bottlenecking capacity from 4400 machines per year to 6000 machines per year. It has already achieved the level of 5000 machines per year. This will enable the company to generate 2500 crores of revenue.

IInd and IIIrd Phase: they have land available and can add three times more revenue.

Hence, total peak revenue could be about 10,000 crore per year

Overall direction of the business:

The current market cap is around 17,000 crore. How big is the opportunity? Does it look like a 10x in 10 year opportunity or this is just a trade?

India is very much focused on atmanirbharta (self-reliance) in key manufacturing areas like defense and electronics. This company will benefit from creating an ecosystem for manufacturing in these areas. There are green shoots already with the number of iPhones made in the country and defense exports of ~21,000 crore in FY2024.

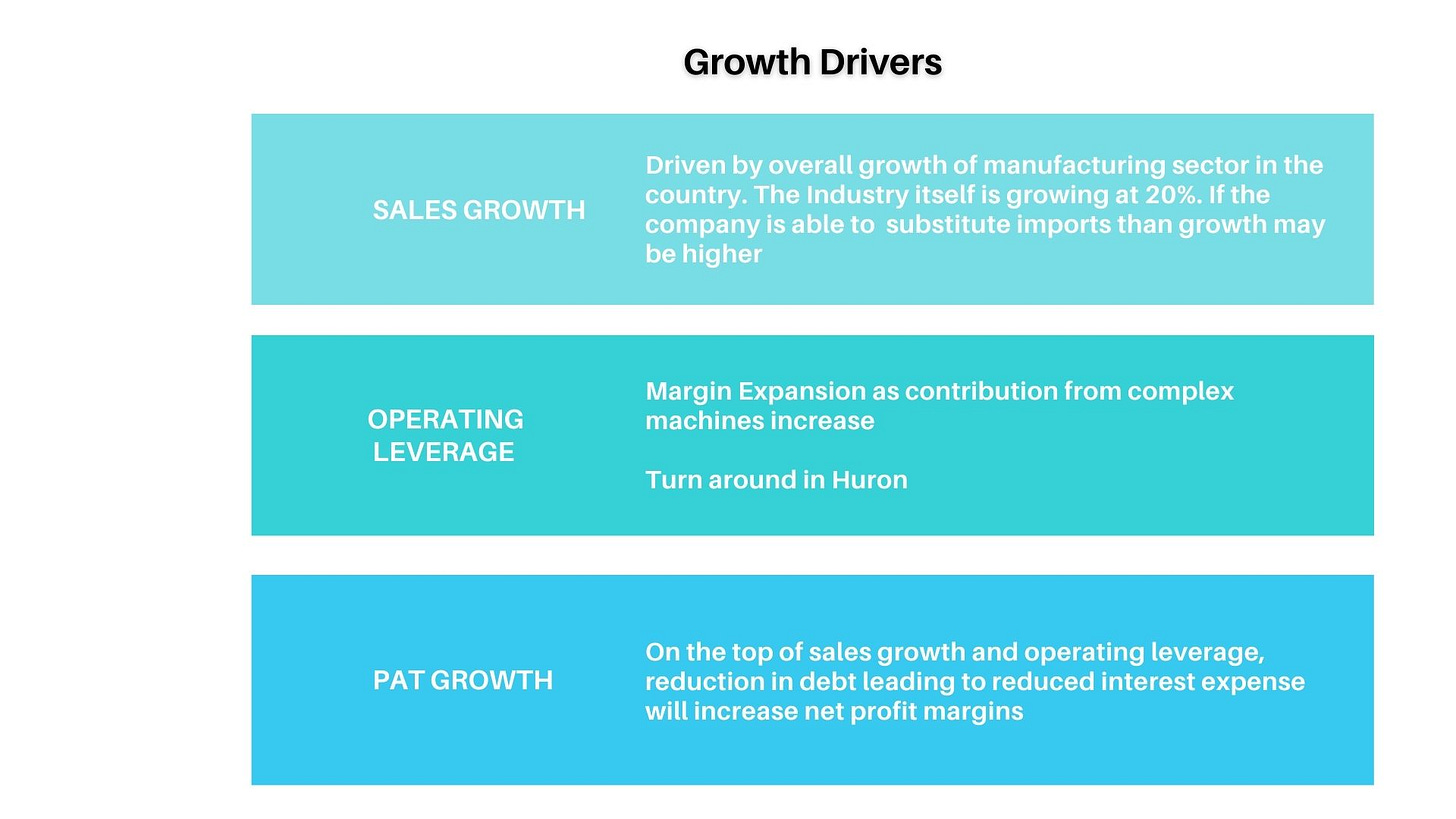

As per management, India consumed $3 billion worth of CNC machines last year (approximately 24,000 crore), of which 65% were imported while 35% were domestically produced. Over the next 5–7 years the consumption is expected to grow at 20%.

Overall market the entry level is domesticated 80–85% is domestic while in high-end machines, 90% is imports. the companies focusing on this high end of the market, where competition is mainly from Germany and Japan.

The company eyes that the proportion of imports will decrease in the next 5-7 years i.e. import substitution is likely to happen. Secondly, the market itself is growing at 20%.

Final Thoughts - Will it cross the chasm??

So the opportunity is there, or we can say the potential is there but will it cross the Chasm, especially when the competition is from Japan and Germany? Management has acknowledged that China itself consumed 95% of the machines from Japan and hence a tough market to crack.

Some snippets from management:

Well, the management tone is bullish. However, as an investor, we should not be carried away by the narrative. CNC machines are substantial investments and crucial requirements of a manufacturing setup, especially in the higher end of the value chain i.e. the complex machines for more precision use cases in industries like Aerospace and EMS. If they are able to cross the chasm then it might turn out to be a long-term compounder.

*****

Invest in yourself…. be a learning machine

These communities have helped me a lot in learning the nuances of investing. Why not check them out? - Join the community of learners.

This Substack will never be paywalled. I don’t want to accept voluntary payments for future unknown work.

But if you got this far, chances are you find my writing valuable. So please spread the word! Sharing, liking, and commenting all help spread the word! 😀

Thanks for reading. Please do share your feedback.

Connect with me on Twitter: @pankajgarg_ciet

Disclaimer: I am not SEBI registered. The information provided here is for educational purposes only. This is not buy or sell advice. I will not be responsible for any of your profit/loss based on the above information. Consult your financial advisor before making any decisions.

Disclaimer: I may have a position in the company. It will be safe to assume that my views are biased.